PRODUCTS

Dold Panels are made of Spruce, Pine, Larch, Thermowood and Accoya

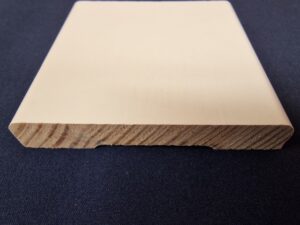

Single-layer edge-glued wood panels

- Panels for furniture construction by craftsmen

- Panels for DIY items

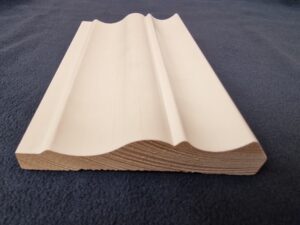

- Mouldings

- Window sills

Dold 3- and 5- layer panels

The three- and five-layer cross-laminated timber panels are high-quality products which are designed for construction and industrial sectors.

The products of Dold can be used in the furniture industry, renovation, interior design, and building structures. The panels have decorative finishing and are ready for installation on ceilings or walls.

Dold first marketed three-layer cross-laminated timber panels in 1982. New gluing and processing technologies were taken into use and are being gradually updated.

The product selection:

- Three- and five-layer cross-laminated timber panels with thicknesses up to 60 mm

- Special-size, in both length and width, board panels (maximum 2,500 mm × 5,950 mm)

- Special sizes can be ordered based on the needs of the customer

Technical specifications (three- and five-layer panels):

- Lengths: 5,000 and 5,950 mm (special lengths can be ordered based on the needs of the customer)

- Widths: 1,025, 1,250, 2,050, and 2,500 (special widths can be ordered based on the needs of the customer)

- Thicknesses of three-layer panels: 13, 16, 19, 21, 27, 32, 42, 52, and 60 mm

- Thicknesses of five-layer panels: 35, 42, and 50 mm

Certificates and environmental requirements:

- The Dold cross-laminated timber panels are suitable for using in construction. Certificate: EN 13986

- Gluing certificates: EN 13353 SWP 2 and 3

- CE certified

Surface treatment and finishing

We offer panels with unfinished, sanded, brushed, and finished surfaces.

Surface treatment with paint:

Water-based paints are used for finishing. The Dold three-layer cross-laminated timber panels can be ordered with formaldehyde-free gluing and oiled surface (Rubio Monocoat). The panels are suitable for use in interior finishing and whether proof external surfaces. For example, the panels may be recommended for emission-sensitive buildings, such as schools and kindergartens.

The advantages of Rubio Monocoat:

- Natural ingredients

- 0% VOC, no water or solvents.

- Easy to maintain and repair.

Surface finishing:

The panels can be ordered with a sanded or brushed surface. The Dold spruce panels can also be thermo treated to completely lose all humidity and get a dark surface.

Finishing:

- Profiled panels based on the needs of the customer (CNC machined)

- Processed edges (tongue/groove)

- Erle Nõgene

- +372 43 525 13

- contact@dold-estonia.com

- Oleg Solovjov

- +372 43 52535

- oleg.solovjov@dold-estonia.com